Petersen Structural Rigging Ltd

Petersen Structural Rigging Ltd

Stainless Steel Architectural Tension Cable Systems

Petersen Structural Rigging are a UK manfacturer of tension cable assemblies with assembly facilities in the UK, Sweden and in Malaysia to service the East Asian region. Petersen have been supplying the architectural tension structures market for over thirty years. All Petersen wire fittings and tensioners are manufactured in house from European material. Petersen only use solid bar and none of our architectural cable assemblies include any cast or welded components. Petersen supply structural solutions in 3mm to 32mm diameter stainless steel wire rope and can supply compacted strand or Dyform stainless steel strand, allowing higher axial stiffness and eliminating the need for pre-stressing, in applications that would otherwise require it.

Petersen is a quality assured UK manufacturer and our production facility is certified by Lloyds Register to ISO9001 and AS9100 quality standards. Petersen have full materials traceability and can provide certificates of chemical and mechanical analysis, certificates of conformity and test certifictes on a case by case basis. Our manufacturing facility and experienced support team have an established track record of quality, cost and delivery on projects of all sizes.

Structural Cable Systems allow a reduction in diameter from traditional steelwork, minimising visual impact of supportive structures and maximising light and space within the building.

Cable Tension Members are typically used to span long distances or in applications where the bend in the cable is used to provide tension to whatever is attached along its length - for example Catenary Cable Systems, Bow Struts / Bow Truss Glass Wall Supports, Cable Net Structures and Tensile Fabric Structure boundary cables.

Please click on one of the images below for full techincal information.

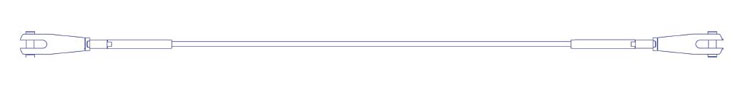

System C1

Stainless steel swaged structural cable assemblies with swage studs fitted at each end. Typically supplied with right hand threads for bolting through steelwork. Can be supplied with left hand/right hand thread combination for threading directly into steelwork.

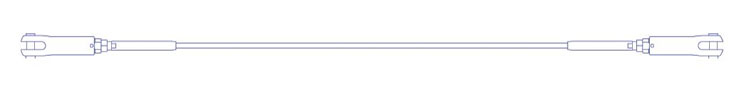

System C2

Symmetrical structural cable assembly using stainless steel architectural adjuster forks of opposing threads, allowing the length to be adjusted without inducing turn in the wire. The tapered adjuster fork gives a smooth visual transition from the tension member to the steelwork.

System C3

Symmetrical tension cable assembly using compact tensioners. Tension can be applied from both ends separately without turning the stainless steel cable. Particularly suited to bow string truss applications.

System C4

This structural tension cable assembly has a swaged fork terminal at one end and a fork adjuster (often called a rigging screw) at the other. The adjuster allows tensioning from one end without turning the cable.

System C5

An architectural wire assembly similar to System C4 but with the addition of stainless steel toggles at each end giving an additional plane of articulation and ensuring correct alignment with the steelwork.

System C6

Stainless steel structural tension cable assembly with a swage fork fitted each end of the wire rope - dead length. Good for hangers or where the structure can be adjusted to apply tension.

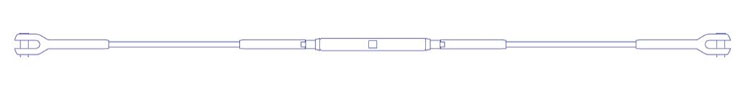

System C7

Symmetrical structural cable assembly with in-line tensioner at the mid-span. The wire rope will not rotate during adjustment.

System C8

A similar system to System C4 above, the structural cable assembly is terminated using self-fit swageless terminals allowing for assembly on-site without special equipment.