Petersen Stainless Rigging Ltd

Petersen Stainless Rigging Ltd

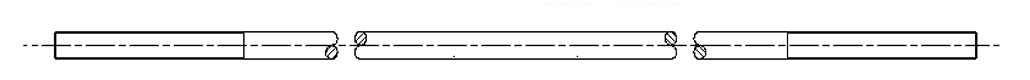

System B3

The System

The SBS-450 range of tie bars are manufactured from a high quality stainless steel grade 316 with rolled threads to BS3643. Manufactured to order and available up to 6m lengths. Longer lengths are available by using bar couplers.

SBS-450 Bars are generally used on

- Membrane Structures

- Lightweight Steel Structures

- Footbridges

- Glass Facades

| Product Code | Thread (Metric) | Ultimate Stress (kN)* | Yield Stress (kN)* | Stress Area (mm²) | 2 Yield Load (kN)* | Ultimate Load (kN)* |

|---|---|---|---|---|---|---|

| SBM10 | M10 x 1.50 | 700 | 450 | 58 | 26.1 | 40.6 |

| SBM12 | M12 x 1.75 | 700 | 450 | 54 | 37.8 | 58.8 |

| SBM16 | M16 x 2.00 | 700 | 450 | 157 | 70.7 | 109.9 |

| SBM20 | M20 x 2.50 | 700 | 450 | 245 | 110.3 | 171.5 |

| SBM24 | M24 x 3.00 | 700 | 450 | 353 | 158.9 | 247.1 |

| SBM27 | M27 x 3.00 | 700 | 450 | 459 | 206.6 | 321.3 |

| SBM30 | M30 x 3.50 | 700 | 450 | 561 | 252.6 | 392.7 |

| SBM33 | M33 x 3.50 | 700 | 450 | 694 | 312.3 | 485.8 |

| SBM36 | M36 x 4.00 | 700 | 450 | 817 | 367.7 | 571.9 |

| SBM39 | M39 x 4.00 | 700 | 450 | 976 | 439 | 638.2 |

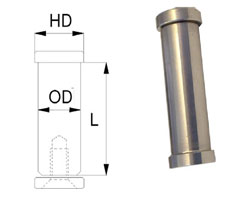

Clevis Pin

| Product Code | L (mm) | OD (mm) | HD (mm) | C/S Screw |

|---|---|---|---|---|

| BDHP10 | 25 | 10 | 12.7 | M3 x 6 |

| BDHP12 | 32 | 12 | 14 | M5 x 12 |

| BDHP16 | 40 | 16 | 19 | M5 x 12 |

| BDHP20 | 50 | 20 | 24 | M6 x 12 |

| BDHP24 | 60 | 24 | 28 | M6 x 12 |

| BDHP27 | 70 | 27 | 28 | M6 x 12 |

| BDHP30 | 75 | 30 | 35 | M8 x 16 |

| BDHP33 | 80 | 33 | 38 | M8 x 16 |

| BDHP36 | 90 | 36 | 42 | M8 x 16 |

| BDHP39 | 100 | 39 | 45 | M8 x 16 |

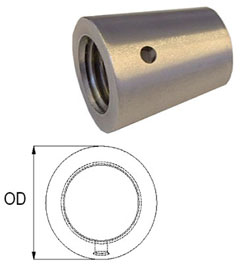

Taper Lock Nut

| Product Code | TH (mm) | OD (mm) | L (mm) | C (mm) |

|---|---|---|---|---|

| TLNM10 | M10 x 1.50 | 15 | 17.0 | 3.5 |

| TLNM12 | M12 x 1.75 | 19 | 20.4 | 3.5 |

| TLNM16 | M16 x 2.00 | 25 | 27.2 | 3.5 |

| TLNM20 | M20 x 2.50 | 30 | 34.0 | 3.5 |

| TLNM24 | M24 x 3.00 | 36 | 40.8 | 3.5 |

| TLNM27 | M27 x 3.00 | 42 | 45.9 | 4 |

| TLNM30 | M30 x 3.50 | 45 | 51.0 | 4 |

| TLNM33 | M33 x 3.50 | 48 | 51.0 | 4 |

| TLNM36 | M36 x 4.00 | 54 | 61.2 | 5 |

| TLNM39 | M39 x 4.00 | 60 | 66.3 | 5 |

Technical Data

The Hi-MOD SBS450 bars are manufactured from stainless steel grade 316 EN10088 1.4401/4 which offers higher corrosion resistance. The pins are designed in accordance with BS 5950-1:2000 and EN 1993-1-8:2005. All components are produced at our manufacturing facility in the North of the England using the latest technology in CNC equipment and produced in accordance with our quality systems . Bar lengths are available up to 6m. Lengths exceeding 6m are also available by utilising a bar coupler. All accessories are finished to a N4 standard (240 grit satin). Bars are produced to a bright drawn finish.

NOTE: If the forks are at maximum adjustment then half a diameter of thread will be visible after the Taper Nut has been fully tightened. Modulus of Elasticity 200N/mm2