Petersen Stainless Rigging Ltd

Petersen Stainless Rigging Ltd

System B1

The System

Tension Bars, also known as Tension Rods, Tie Bars and Tie Rods, are manufactured in the UK by Petersen.

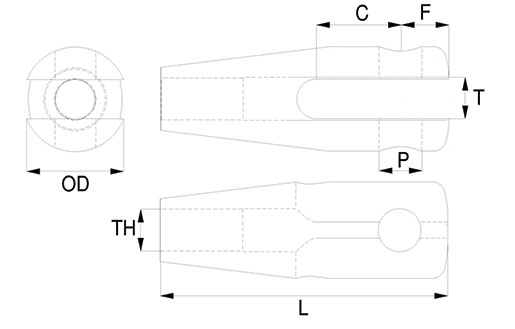

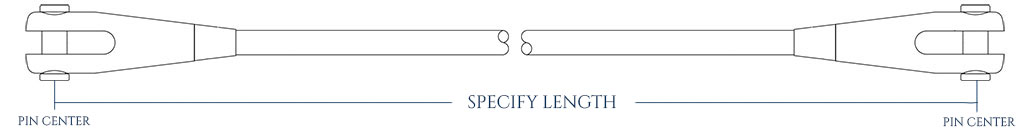

Tension Bar systems consist of a threaded stainless steel tie terminated with an SBS-450 fork clevis adjuster at each end. The SBS-450 fork and clevis pins are designed in accordance with BS5950-1:2000, EN 1993-1-11:2006 and EN 1993-1-8:2005 and are machined - not cast - from a high-strength duplex stainless steel.

The SBS-450 fork clevis ends allow a generous amount of adjustment and are normally supplied in pairs with one left hand and one right hand threaded end. After installation the Tension Bar can be rotated to set the correct length and locked into position using tapered lock cover nuts.

316 Tension Bars are manufactured from specially drawn high-tensile bar-stock with rolled threads. Tension Bar systems are available in up to 6m single lengths and couplers can be used to span further.

| Product Code | Thread (Metric) | Pin (mm) | T (mm) | C (mm) | F (mm) | ADJ +/- (mm) | OD (mm) | L (mm) | 0.2% kN* | UTS kN* |

|---|---|---|---|---|---|---|---|---|---|---|

| B1-M10 | M10 x 1.50 | 10 | 10 | 20 | 11.2 | 20 | 25 | 68.7 | 26.1 | 40.6 |

| B1-M12 | M12 x 1.75 | 12 | 12 | 24 | 13.8 | 24 | 32 | 82.8 | 37.8 | 58.8 |

| B1-M16 | M16 x 2.00 | 16 | 15 | 32 | 18.4 | 32 | 40 | 109.9 | 70.7 | 109.9 |

| B1-M20 | M20 x 2.50 | 20 | 19 | 40 | 23.0 | 40 | 50 | 137.5 | 110.3 | 171.5 |

| B1-M24 | M24 x 3.00 | 24 | 24 | 48 | 27.6 | 48 | 60 | 165.6 | 158.9 | 247.1 |

| B1-M27 | M27 x 3.00 | 27 | 26 | 54 | 31.1 | 54 | 70 | 185.9 | 206.6 | 321.3 |

| B1-M30 | M30 x 3.50 | 30 | 29 | 60 | 34.5 | 60 | 75 | 206.5 | 252.6 | 392.7 |

| B1-M33 | M33 x 3.50 | 33 | 32 | 66 | 38.0 | 66 | 80 | 227.3 | 312.3 | 485.8 |

| B1-M36 | M36 x 4.00 | 36 | 34 | 72 | 41.4 | 72 | 90 | 247.4 | 376.7 | 571.9 |

| B1-M39 | M39 x 4.00 | 39 | 38 | 78 | 44.9 | 78 | 100 | 268.7 | 439.2 | 638.2 |

| B1-M42 | M42 x 4.50 | 42 | 40 | 84 | 48 | 168 | 100 | 289 | 504.5 | 784.7 |

Technical Data

The Hi-Mod SBS450 bars are manufactured from stainless steel grade 316 EN10088 1.4401/4 which offers higher corrosion resistance. The pins are designed in accordance with BS 5950-1:2000 and EN 1993-1-8:2005. All components are produced in accordance with our quality systems. Bar lengths are available up to 6m. Lengths exceeding 6m are also available by utilising a bar coupler. All accessories are finished to a N4 standard (240 grit satin) other finishes are available on request. Bars are produced to a bright drawn finish.

NOTE: If the forks are at maximum adjustment then half a diameter of thread will be visible are the Taper Nut has been fully tightened. Modules of Elasticity 200N/mm2.